|

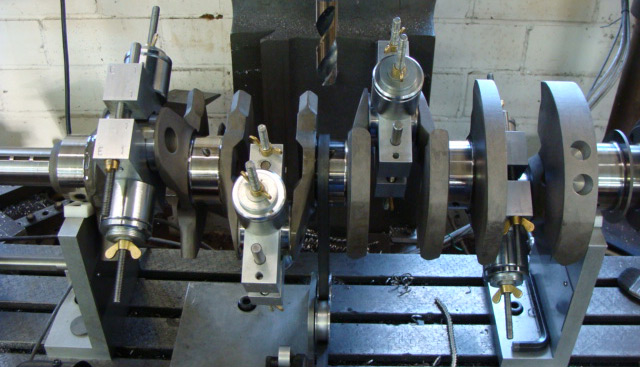

| This is our new Ohio Crankshaft 4.750" stroke Pro-Max crank getting a little work done to it before final balancing. |

This sounds like it should be a simple tech feature. Order a Dart Big M block. Tall deck with billet main caps and 4.600" bore. All I need to do is take my rotating assembly out of the damaged block and put in the Dart block. "What was I thinking?" Remember, I am not an engine builder or a machinist so I am a little naive when it comes to aftermarket race engine blocks and the prep work required.

I will make this story as short and to the point as I can. The new Dart Big M iron block is without a doubt a heavy-duty piece of equipment and will be a fantastic foundation for the Project 632 bracket engine we are building. When Roeder Performance Machine got the block they did the standard visual inspection and did not find anything major as far as flaws or damage from shipping.

|

| We had to do a little de-burring to smooth out the casting on the Big M. Could have run it without doing this, but we decided it was better to smooth it out to eliminate stress risers and make it easier for oil to flow back to the oil pan. |

|

| After cleanup the Dart Big M is ready to be assembled. |

The Big M is cast iron so there was the usual clean-up of casting edges and normal de-burring that had to be done. We did find out I needed a different set of head-studs from ARP as the ones out of the old aluminum block are different.

Dart does make a special kit for the head bolts that are in the lifter galley but we couldn't find one available locally so Jay Roeder fabricated some spacers that worked out fine. These are critical in our opinion if you run high compression or NOS. I recommend you order the lifter galley head bolt kit when you order the block.