Jay used the larger Comp

Cams degree wheel. It is easier to read and

the larger diameter makes it easier to get "exactly

to the degree" you are looking for. Comp Cams

was instrumental in working with us to custom

grind our roller camshaft. This is a typical

service they offer any racer and if you are

serious about the power you make just call them

and one of their customer service tech people

will help you out. There is no "special fee"

for this personal service it is just the way

they do business.

The Roeder Performance Machine 572 Mopar then

made back-to-back pulls with a peak horsepower

of 958 HP at 7200 rpm and peak torque of 806

ft./lbs. at 5600 rpm. We ended up at 35 degrees

of timing with VP-16 racing fuel. We will probably

turn the timing back to about 32 degrees for

1/4 mile racing and leave it at 35 when we run

tracks with great starting lines like Eddyville

and CFR. If you haven't been to a dyno session

with a big inch engine sitting on the dyno and

feel and hear it hit 7600 under full load, you

are missing something. When I heard and watched

it and had paid for the engine I thought I was

missing something ... my mind! What was I thinking

standing there watching these guys run my engine

flat-out and no "pipe rack" wrapped around it?

It was GREAT, SCARY and EXHILARATING all at

the same time. The engine ran perfect.

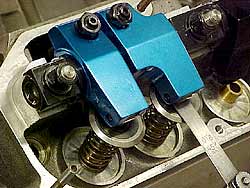

Roeder Performance

Machine installed a set of light pressure

"checking springs" and used the rocker arms,

pushrods, retainers and keepers we would

be racing with when he put the heads on

to check piston-to-valve clearance. It is

"absolutely critical" to always check piston-to-valve

clearance. Just because you think it should

be OK it isn't. Many engines have been destroyed

because piston-to-valve clearance was too

tight and they ended up with the valve hitting

the pistons and valves breaking off and

destroying pistons, cylinder walls and more.

Take the time to check it. |

After a mad thrash to get the motor home out

of storage and the trailer cleaned out and "sort

of organized", it was time to finish the car.

Several companies helped make it happen and

I want to mention them just in case you are

looking for a part they offer. I hope you will

support the companies that have supported "Project

4-Link" the last few years. Barry Grant / Demon

Carburetors provided a deadly matched set of

tunnel ram King Demon RS. RCI had just what

we needed to update our safety harness, engine

diaper that is now required in Top Dragster

and a set of fire pants and jacket for Andy.

Indy Cylinder Head produces a tunnel ram intake

that was flat-out amazing in the power gains

it provided. Flat-Out Gaskets made a custom

set of rubber-coated copper head gaskets for

our 4.500" bore Mopar. Comp Cams worked with

us in designing a roller cam that would match

the heads, intake and our plans. Chris did a

great job and his service at Comp Cams was extremely

thorough and the roller lifters, springs, retainers

and 10-degree keepers all fit perfectly. CP

Pistons worked with the engine builder to produce

a light piston and ring package that will offer

durability and excellent performance. Steve

Stokes dragged over his new TIG Welder and put

in the helmet bars I am required to have. Steve

owns a local metal fabricating shop and this

was his first time welding on a chrome-moly

dragster chassis and his workmanship was superb.

THANKS Steve, reminded me of the "old days"

when doctors made "house calls"!

Here is the "crew".

On the dyno controls is Jeff Stealy, in

the foreground is my son, Andy, who will

do most of the Top Dragster driving and

in the background is "Mr. Horsepower", Jay

Roeder. (I had to poke him to keep him awake

UNTIL THE ENGINE WAS RUNNING!) Man, did

that big Mopar sound GOOD at 7500 rpm!

|

We finally got everything loaded and began

out first outing in Top Dragster trim. We are

headed to the NHRA Spring Challenge XII at St.

Louis Int'l Raceway in IL. I was fortunate enough

to have won that event last year in Super Comp

and this year we will give it a try in the JEG'S

Super Quick Series. Of course we have to ACTUALLY

QUALIFY for that race. Look for the results

in my mid-month update. I'll go over our actual

runs, what we learned about converters, etc.

in our first ever JEG'S Super Quick Series event.

You will hear from me in a couple of weeks.

Race safe my friends ...

|

Previous

Story

|

Project

4-Link

—

3/10/04

Building a 572ci Mopar Wedge Motor for Project

Top Dragster |

|