ADVERTISEMENT

|

Most Mopar racers have tried

grinding the rocker arm for additional clearance, installing

the smallest diameter and strongest valve springs and even

trimming the edges of titanium retainers so they would clear

the rocker arms. These all work, but only temporarily, as

the grinding weakens the rocker arm and it is inevitable that

it will fail prematurely. Personally, breaking two to four

rocker arms and the resulting damage to roller lifters and

pushrods was getting old. I was lucky in that I have never

really hurt anything else, but breaking an exhaust rocker

and putting the extra pressure on that cylinder’s connecting

rod and bearing could cause a major engine failure.

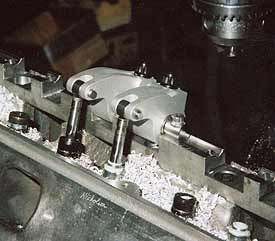

First trial

fit. The mounting plate is in place and torqued down.

The rocker arms are assembled and bolted down in pairs.

We are using 1: 6: 1 ratio and exhaust is offset .750"

on Indy 440-1 heads.

|

I started looking around for

a cure for this common Mopar problem. I ended up talking to

Jesel Rocker Arms at the PRI Show last winter. I looked over

what they offered and decided it was time to bring modern

technology to my 970 H.P. Mopar. The Pro Series kit for my

model 440-1 Indy Cylinder Heads comes with the absolute finest

mounting hardware, detailed instructions, fixtures to assure

proper rocker arm shaft height, and a reputation for the finest

rocker arms available at any cost.

Rather than keep you guessing, a Pro-Series Jesel rocker

arm assembly for the 440-1 Mopar heads will set you back about

$1400.00 if you go for the extra milling to lighten them up

even more. Standard kits for the Mopar run about $1200.00

for Mopars and a few hundred less for Chevrolets.

Installation and prep work is very well explained and diagramed

in the installation instructions. There is a bit more involved

when doing a Mopar because the rocker shaft pedestals have

to be milled off so the new Jesel Rocker Arms can be bolted

to their mounting plate.

I trusted the machine work and milling to R&J Performance

in Hudson, IA. Keith “Woody” Briden has done work

for me for over 15 years and just like in the past I was not

disappointed. The photos pretty much tell the story of setting

up the Indy heads (or any big block Mopar head for that matter)

for the milling process to remove the rocker shaft pedestals.

|

|

|

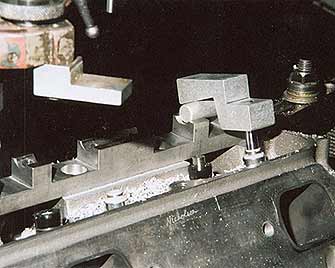

| Initial milling on the

rocker shaft pedestals. They were milled down .600"

then trial fitting started. |

This is the fixture that

Jesel supplies to let the machinist know when the depth

of the milling is correct. The fixture will fit flat on

the top of the valve when the height of the mounting plate

is correct. |

After the plate height

is correct, the mounting plate needs to be bolted down.

This requires using the five original threaded holes and

adding four more so the billet plate does not flex. |

The fixture Jesel provided to assure proper installed height

of the mounting plate is simple to use and deadly accurate,

as it all came out just right. As in all machining accuracy

and patience will produce the results you are looking for.

In this case the Jesel Rocker Arm system went together as

designed.

|