This broken

rocker arm is what sent me on the search for an economical

rocker arm that would last more than one season. You can

see the break on the bottom of the rocker arm.

|

The Stage

VI Mopar heads on this engine uses all OEM style valve

gear. The rocker arm shaft pedestals, mounting bolts and

oiling system are all stock design. |

After determining

what length pushrod we needed a call to Comp Cams and

two days later we had the set of HiTech pushrods we needed.

We used part number 7934-16, which are different than

OEM in that both ends are "ball-style" and not

"cup-style" on one end.

|

This is

the Pro-Magnum kit #1321-16 for big block Mopars. Now

is the time to have your rocker arms honed out to assure

.004-.006" clearance if you are using a roller cam

or cam lift over .600". Take the shafts and rocker

arms to a competent machine shop. This is a simple and

inexpensive operation but can save you hundreds of dollars

in the long run. |

One reminder

as you install the rockers on the shafts. You have to

determine which side you are setting up because the oil holes

are not in line with the mounting holes. Make sure the

oil holes are pointed towards the outside exhaust side

of the head. This will assure correct oiling when the

rocker arm is lifting the valve spring and valve.

|

Comp Cams,

myself and most engine builders agree that it is critical

to use a moly-based assembly lube on an assembly like

this, especially for initial startup to prevent galling

of rockers to the shaft. It is a good idea to make sure

you pre-lube the roller tip as well. |

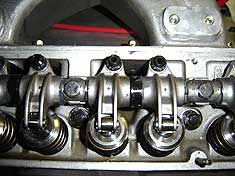

This is

how the rocker arms looked after some minor grinding on

the stamped-steel spacers. Try to get the rocker centered

on the top of the valve and be sure to have .035-.040"

side clearance per pair of rocker arms. Even though it

is a little more work, the best results setting side clearance

and positioning of the rocker tip on valve is best done

without pushrods being installed.

|

A little

closer view of the installed rocker arms. The spacers

are easily visible and easily filed off to provide the

correct side clearance. Positioning over the tip of the

valve is important, try to keep them as centered on the

valve as possible. |