|

|

|

|||||

|

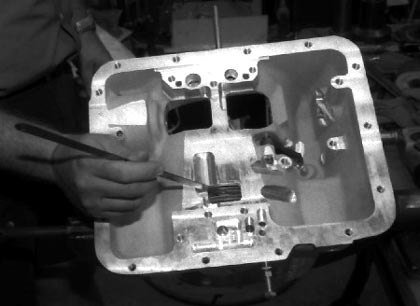

Pure power isn't the only thing that can kill a Powerglide case. The stock bellhousing can crack or break from chassis flex, tire shake, or from being dropped on the ground, with the damage often extending into the case itself. (If the case is fine, lopping off the bell and installing an UltraBell can fix this.) The transbrake solenoid can blow out of the case, or the area around the fluid line fittings can crack without a whole lot of torque being applied to the fittings. Any of these can render an otherwise functional transmission completely useless. To solve the case problem Winters designed and built a replacement for the stock unit and called it the UltraCase. Although it accepts all Powerglide internals and, with the UltraBell attached has the same overall dimensions, the resemblance pretty much stops there. The fluid passages have been redesigned specifically for the task at hand, the pan-mounting rail is thicker and wider for better sealing, and the case has been strengthened in all of the weak-link areas. This includes the beefy mounting pads for the fluid lines and trans-brake solenoid. Additionally, J.W. whittles new servos and covers out of aluminum billet. Coupled with the extra material around the servo boss, this aids in the consistency, longevity and performance of the transmission by increasing oil flow, providing better sealing, and extending the life of the bands. The UltraCase also features an adjuster that determines the rate of

transbrake release. This lets a racer dial-in how hard the tires hit

the track at the launch, to compensate for varying track conditions.

An air-bleed circuit that keeps the transbrake system filled only with

fluid is incorporated in the design, eliminating any rocking on the

starting line when the brake is applied. And for those who want to keep

an eye on the temperature and pressure of the fluid, a port is provided

for a gauge to monitor these functions.

|

||||||

|

Copyright 1999-2002, Drag Racing Online and Racing Net Source |

||||||