One thing you'll notice

on both types of shocks (vintage Hal Corp and

Competition Engineering) is the lack of dust

covers or shields. These are race shocks and

because of that, there's no need for the extra

hardware.

C-E shocks are adjusted by turning the upper

collar on the body. Adjust the shock by aligning

the notch on the collar with the adjustment

setting range on the shock. Each front shock

has an adjustment range of 10/90, 20/80 and

40/60. The first number (as an example, the

"10" in a 10/90 combo) corresponds to the percentage

of energy required to extend the shock (rebound)

while the second number refers to the energy

required to compress (bump) the shock. In drag

racing terms, that's the same as a 90/10, 80/20

and 60/40.

The C-E shocks are adjusted

by turning the upper collar. You adjust the

shock by aligning the notch on the collar with

the adjustment setting range on the shock. Each

front shock has an adjustment range of 10/90,

20/80 and 40/60. In drag racing terms, that's

the same as a 90/10, 80/20 and 60/40.

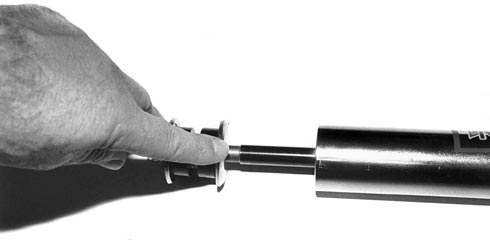

The C-E shock must be removed from the car

to set the valving. Here's the drill: Before

you make any attempt to set the valving, hold

the shock upright and run it through it's travel

ten or twelve times (this might take some serious

muscle power initially). This purging effectively

removes any aeration inside the shock. If you

"stroke" the shock upside down or sideways,

air is allowed into the shock and you won't

get the adjustment right. Next, the shock is

fully depressed (remember to maintain the upright

orientation) and you have to line up the notch

on the collar with the setting range on the

shock body. With the shock still depressed,

the adjustment collar is rotated clockwise until

a click is heard. This means that the internal

adjustment mechanism is now engaged. Basically,

you have to rotate the notch on the indicator

until it reaches the desired setting ("XF",

"F" or "R"). You can now reinstall the shock.

These are the stamped

setting codes on the body of the C-E shock:

"XF", "F" and "R". The break down is as follows:

"XF" = 40/60; "F" = 20/80; "R" = 10/90. If the

shock is set at "R" or 10/90, then it only needs

10 percent of the total force to extend it.

To compress the shock, 90 percent of the force

is used.

|