|

As the Dalai Lama will tell you, balance is

one of the keys to achieving greater consciousness. For drag

racers, consciously building a balanced engine is the key

to greater performance. . . or so the Dalai Lama of high

performance will tell you.

But unbelievable as it may seem, there are still a number

of successful drag racers who believe that a stock original

equipment harmonic damper will work perfectly fine with your

drag racing engine. Wrong. The fact is that using an original

equipment damper is not only a mistake, but dangerous, and

could be stealing horsepower potential from your engine.

Here’s why.

Vibration can be controlled either by dissipating the energy

that causes the crankshaft to twist or by absorbing that

energy. A stock damper is tuned to the natural vibration

frequency of a stock engine. As soon as you change the internal

dynamics of an engine, such as by adding a performance crankshaft

or changing the pistons and valvetrain parts, you change

the frequency. To return to optimum performance you need

to re-tune your damper to your performance engine. Stock

cast iron elastomer dampers just can’t handle that

task and reduce your performance potential.

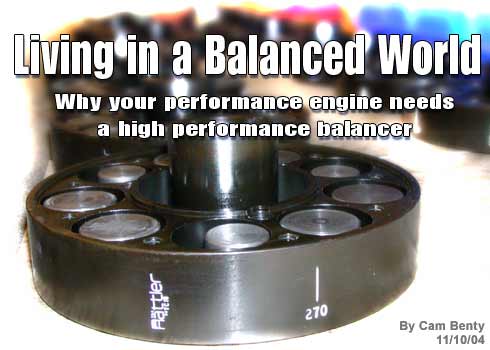

High performance, SFI-approved devices like the TCI Rattler

are actually tuned to the number of engine cylinders and

engine cycles, which means that maximum effectiveness is

ensured regardless of engine modifications. Energy absorption,

common only to the Rattler, provides torsional control by

providing counteracting forces to those that actually cause

torsional vibration. Devices like the TCI Rattler actually

absorb the crankshaft-damaging twisting forces through the

movement of weighted “pucks” that store and release

energy as the crankshaft accelerates and decelerates. High performance, SFI-approved devices like the TCI Rattler

are actually tuned to the number of engine cylinders and

engine cycles, which means that maximum effectiveness is

ensured regardless of engine modifications. Energy absorption,

common only to the Rattler, provides torsional control by

providing counteracting forces to those that actually cause

torsional vibration. Devices like the TCI Rattler actually

absorb the crankshaft-damaging twisting forces through the

movement of weighted “pucks” that store and release

energy as the crankshaft accelerates and decelerates.

Other types of dampers, such as high performance elastomer,

dry friction and viscous-type dampers, work like OE dampers

by dissipating the vibrations by converting mechanical energy

to heat energy through friction. While this kind of damper

is a better choice than the stock unit, heat is always the

enemy of any engine part and in this case results in degradation

of the working mechanism over time.

“Stock cast iron OE elastomer dampers are not made

for high rpm situations,” says Stanley Poff of TCI. “Cast

iron dampers can crack and break with age ultimately exploding.

In addition, that elastomer system often 'slips' and can

even move far enough to release the outer ring making for

a very dangerous situation. True high performance balancers

are made from forged or billet steel and cannot come apart.”

Eliminating torsional vibration improves the acceleration

rate of the engine. This means that through high tech engine

vibration analysis, engine rpm cycles are smoother and crankshaft

and bearing life increases which results in more efficient

valvetrain operation. The cost-saving rationale many racers

use to justify avoiding the expense of purchasing a high

performance balancer just doesn’t work when you think

about the added costs incurred when valve train parts and

bearings are damaged. Eliminating torsional vibration improves the acceleration

rate of the engine. This means that through high tech engine

vibration analysis, engine rpm cycles are smoother and crankshaft

and bearing life increases which results in more efficient

valvetrain operation. The cost-saving rationale many racers

use to justify avoiding the expense of purchasing a high

performance balancer just doesn’t work when you think

about the added costs incurred when valve train parts and

bearings are damaged.

“The part that really amazes me,” says Greg

Friend of TCI, “is that guys don’t realize that

the factory elastomer damper can wear out. Often the outer

ring of the damper has slipped over time. Unfortunately the

timing marks for the engine are on this ring. When the racer

goes to time the engine, they are not using accurate marks.

If your engine performance is lacking and you can’t

seem to find the problem and you are running a stock damper,

you might just want to check the damper!”

A high performance balancer is a required racing part,

as key to high performance as having the right set of rocker

arms or making certain the firing order is correct. A stock

OE damper may have been just fine in your street machine,

but for the serious racer, that balancer represents not only

a safety problem, but can also cost you engine life and optimum

performance.

|