|

This is attempting

to show the degree notches that are used

for advancing or retarding the cam timing.

Instead of removing the crank sprocket or

using small offset bushings you simply rotate

the eccentric to the desired position. NICE!

|

The last thing I want to touch on is valve

clearance. Not having enough can be very bad!

I simply cannot emphasize enough the importance

of checking valve clearance. Once you have the

cam put in its place, assemble a cylinder head

with light checking springs on one chamber and

install it with an old gasket of the same approximate

thickness as the ones you will use. Drop in

the pushrods and rocker arms you will be using

and set a dial indicator up to read the travel

of the valve retainer. Now rotate the engine

over carefully and with your hand gently push

down on the rocker arm tip where it contacts

the valve stem. Doing this at different points

along the way you will find the point of closest

clearance and know what you have. The correct

amount depends on many variables so a call to

a reputable engine builder or cam company would

be wise. The generally accepted clearance would

be .080" minimum. I have some engines running

with only .035" clearance but that is not normally

desired. It's a rules thing. The design of your

valve springs and installed seat pressure can

also have dramatic effects on performance, especially

when the valve clearances become tighter. I

helped a customer with a BBC last year pick

up .15 seconds and almost three mph simply by

increasing spring pressure. Once again, there

is no one perfect pressure for every combination.

It is a matter of trial and error, but I always

lean towards what some people would call the

"over-sprung" end of the spectrum. I have not

seen an example yet where too much spring made

less power. Unless of course you have a flat

tappet cam and wipe the lobes off! Ha, ha!

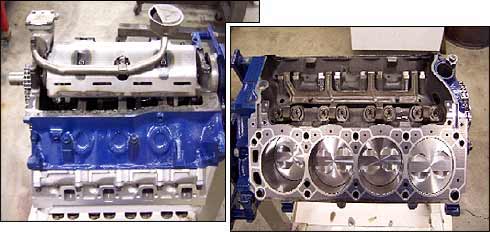

Here we see the bottom

end with windage tray/scraper and the factory

Ford oil pump and pickup tube. CUTLINE: This

is attempting to show the "spider" tray that

keeps the hyd.roller lifters in place. Also,

the Ford Performance head gasket.

Well, the pictures will tell the rest of the

story and I am REALLY looking forward to finally

getting back on the track! Not racing just plain

SUCKS! Next issue I will cover the fuel and

ignition systems along with intake manifold

selection and hopefully have some actual track

results!

Remember, life's too short.

When in doubt, DO A WHEELIE!!

|