|

OK. You’ve finished twisting and turning. Now what?

That’s easy. Cut off the excess length (the excess length

is often called the “pigtail” or “tab”).

The idea is to leave approximately 0.500-inch of twisted wire

sticking out on the back-side of the last bolt or fastener.

With a set of pliers, bend this material back onto itself,

forming a loop (hence the term “pigtail”). You

want the rounded portion of the loop to be what comes in contact

with your hands, clothing or whatever. Let’s just say

the rounded pigtail is less band-aid dependent than a raw

edge of twisted safety wire.

AIRCRAFT PRACTICES…

The aircraft industry is full of established methods of making

things work. What follows is a look at how to correctly safety

wire fasteners, using proven techniques:

|

|

|

|

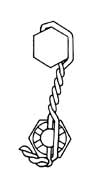

| Illustration 1 |

Illustration 2 |

Illustration 3 |

Illustration 4 |

Illustrations 1, 2, 3 and 4 apply to all types of bolts,

fillister head screws, square head plugs and other similar

parts that are wired together. The idea in each of these cases

is to insure that the loosening tendency of either part in

counteracted by the tightening of the other part. According

to the Standard Aviation Maintenance Handbook: “The

direction of twist from the second to the third unit is counterclockwise

to keep the loop in position against the head of the bolt.

The wire entering the hole in the third unit will be the lower

wire and by making a counterclockwise twist after it leaves

the hole, the loop will be secured in place around the head

of that bolt.”

|

|

|

|

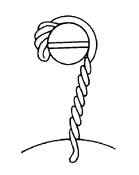

| Illustration 5 |

Illustration 6 |

Illustration 7 |

Illustration 8 |

Illustrations 5, 6, 7 and 8 show the accepted aircraft methods

for wiring various standard items. In these examples the wire

may be wrapped over the unit rather than around it, particularly

when wiring castellated nuts or other items where a clearance

problem may exist.

|

| Illustration 9 |

Illustration Number 9 is different. It shows the correct

procedure for safety wiring bolts in different planes. As

with other safety-wiring tasks, the wire should always be

applied so that the tension is in the direction of tightening.

Illustration Number 9, shows the method used for hollow head

plugs. As pointed out previously, the “pigtail”

or tab should be bent inside the hole to avoid snags and possible

injury to anyone working on the car.

|

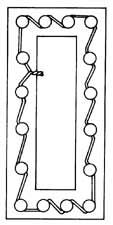

| Illustration 10 |

If you have a group of fasteners that are closely spaced

they can be wired together, as shown in Illustration 10. With

this many components safetied with one wire, there is a possibility

for loosening. As a result, the aircraft industry has a rule

of thumb for such a group of fasteners. It states you should

limit the number of units that may be wired with a piece of

wire 24-inches long.

| Source |

Mr. Gasket

Performance Group

10601 Memphis Avenue, #12

Cleveland, OH 44144

PH: 216-658-6274

|

One final tip when it comes to safety wire: Think about carrying

a mechanic’s magnet with you when safety wiring pieces

together. Why? Simple. Cut-off wire from the pigtail ends

has a nasty habit of ending up in places it shouldn’t

be – and that includes tires. Remember, the pigtail

cut-offs are sharp!

|