|

By Wayne Scraba

6/8/05

It’s been said that some

of the best sealing engines in all of motorsports are found

under the hood of NHRA-legal Stockers. And that could very

well be true. Just take one look at the restrictions facing

a Stock Eliminator racer: Replacement pistons with OEM ring

grooves. Limited creativity with regard to valve configurations

(and valve jobs). No add-ons such as crankcase vacuum pumps.

The methods used to seal these creations is pretty finite,

and one of the keys is the piston ring. Sound interesting?

Read on.

Now, it’s no secret that you can seal an engine pretty

well, but there are also plenty of trade-offs. And the worst

one could very well be ring drag. That’s where Stock

Eliminator becomes an enigma: Use a ring that seals the engine

tight and in many instances, you’ll be met with considerable

drag. The result is wasted horsepower. Of course, there are

plenty of clever racers out there who have figured out how

to have their cake and eat it too: The cost though, is quite

often a bunch of added maintenance: Honing cylinder walls

and re-ringing the engine in short-term intervals.

There’s more here too: Given the rules, a Stocker is

pretty much forced to race with a big, fat ring. At least

that’s what the piston rule more or less dictates. Typically,

most Stockers use a piston with some form of 5/64-inch top

and second ring groove along with a 3/16-inch (or thereabouts)

oil ring package. Big heavy rings such as this (we’re

primarily discussing the top two rings) are fine for low RPM

engines, but when the tachometer needle starts cranking hard

to the right (and more often than not, far beyond the range

the OEM manufacturer originally intended), then ring weight

becomes an issue. That’s one big reason why applications

ranging from Pro Stock to Formula 1 use skinny, light top

rings.

A heavy ring can be terribly upset by flutter. What is flutter?

Ring flutter is believed to be caused by pressure that leaks

by the top ring and but does not get by the second ring. Theory

has it this creates pressure between the top and second ring

that pushes down on the second ring and up on the top ring.

This pressure, during proper circumstances, is said to be

able to lift the top ring off its ring land creating ring

flutter.

There are a couple of theories out there on how to fix this

dilemma: One is to open the gap on the second ring, and allow

the pressure to escape. This might work, but it should also

raise some red flags: If you open the gap, then you’re

inviting blow-by, effectively kissing away the sealing capability

of the ring. It should be no surprise to any of you that filling

the oil pan with combustion gases isn’t a great idea.

And if you have no means to evacuate the crankcase, other

than something like a PCV valve and a breather, it gets even

worse. Blow-by not only robs the engine of power, it shortens

the lubrication life of the crankcase oil and it causes internal

engine parts to wear out prematurely. But in a Stocker, the

biggest problem just might be might be the fact that power

is continuously eroded as the ring gap increases in size.

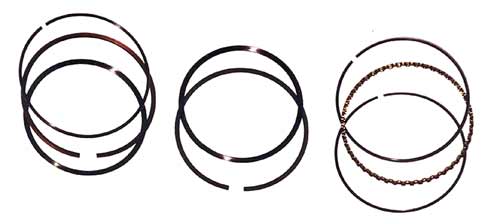

This simply looks like rings. But it’s

not. This is the top ring set from the “Advantage Ring

System” manufactured by Total Seal. It’s targeted

toward the little guy racer and/or enthusiast.

|