|

The design of the bushing is such

that every axis the suspension sees meets with the Del-A-Lum

material. This means that as the suspension moves through

its travel, there is never any metal-to-metal contact, no rubber or urethane

deflection and zero stiction. In the end, this means that the shock absorber

becomes the only controlling factor in the suspension system, and that's definitely

good.

Aside from expensive custom machining and

equally expensive spherical bearings, there is definitely

one other excellent option, and it might not be near as labor

intensive or as costly as my backyard engineered bearing

system. Better still, it's readily available for

countless

applications (early and late, GM, Ford and others) and as

a result, there's no need for one-off fabrication. What

I'm referring to is the "Del-A-Lum" bushing manufactured

by Global West Suspension Components. Global West is

one of the few "turn and burn" street suspension

companies I've personally run across which truly understand

that shock absorber control is the key. In order to

make the suspension work as designed, you have to eliminate

the compliance or deflection from the bushings and make them

as loose (in terms of stiction) as possible. In turn,

the shock then controls virtually all of the suspension movement. If

you don't like the way the car works, then you adjust the

shock, since it's the only real variable. At least

to me, that seems quite logical.

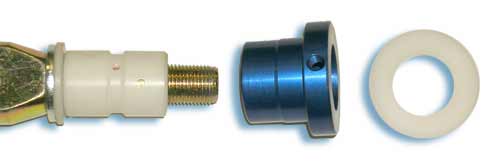

If you take a close look inside

the aluminum bushing housing, you can see that it is

radially machined, which allows grease to travel the

full distance of the assembly. In addition, the

Del-A-Lum insert is designed with radially drilled

holes along with a groove in the center. Again,

the purpose is to allow grease to pass along all moving

points. |

The key in the Global West system is the way the front control

arm bushings are made. Del-A-Lum is an advanced, extremely

dense, extremely hard plastic material (I'm using "plastic" for

lack of a better word, because that's what it resembles --

in truth, Del-A-Lum is a proprietary material). Basically,

the material does not have cold flow tendencies, and as a

result, it has the capability to maintain alignment over

time. In construction, the bushings are multi-piece

affairs. For example, the first generation Camaro bushings

shown in the accompanying photos consist of an aluminum bushing

housing. Inside is a Del-A-Lum insert. On either

end of the bushing housing, a large diameter Del-A-Lum washer

is installed, sandwiched with another large diameter steel

washer. This provides what Global West calls "six

way surface isolation". In other words, every

direction the bushing is stressed (up, down, forward, rearward,

to the left and to the right), the forces see the Del-A-Lum

material. Because of this, there is zero

bushing deflection, no matter what axis the forces represent. When

you take a close look at the photos, you'll see that the

extra thrust washers are designed to control fore and aft

movement without binding up the suspension. Additionally,

(and perhaps most important for a drag race application),

there is absolutely no suspension bind or galling of the

bushing material. Because of these properties, the

vehicle alignment is always maintained, even under hard acceleration,

braking and cornering (which of course, has little consequence

in a drag car). What these properties mean is the suspension

travels freely, all of the time.

|