|

As is my normal procedure I decided to check the crankshaft

endplay before removing the crank and cam. When I inserted

the pry bar between the number 2 main cap and the crankshaft

and gently pried to move the crank my mind about exploded.

“Holy cow, that main cap moved A LOT!“ Sure enough,

if I looked real close I could see a crack in the block. I

removed the caps, crankshaft, and cam. Upon further inspection

the only part of the block main saddle that was actually attached

was about an inch long on one side in the area that has the

main oil galley passage. That is why I still had oil pressure

last fall.

ADVERTISEMENT

|

Once

I grasped the reality that the block was junk, I took a small

ball-peen hammer and gave the main web a couple of “love

taps” and a pie-shaped piece of the block literally

popped straight up out of the block! Man did I get lucky!

This bad boy wannabe was about half a burnout from having

a serious oil pan failure! From what I can surmise the block

and spindly crankshaft had flexed enough to let the CP Pistons

cock in the bores and rub the rings to an early demise. But

hey, I’m not complaining. It could have been a WHOLE

LOT worse! Luckily the rotating assembly was saved and the

pistons weren’t hurt so a new block was in order.

What to use for a block was the next question. I had read

other articles over the years about the weakness of the late

302 roller blocks and how some of them actually break in half

when you reach the 450 to 500 hp level but I never figured

on having a problem. I do remember however in one of my first

articles covering this potential problem and saying “hope

for the best.” Oops. The initial plan was to build a

bigger engine but time was fleeting and I really wanted to

race this year. The hopes for chasing the IHRA Division 5

points had been dashed a couple months earlier when IHRA corn-holed

all of the people who had supported them in this area when

they decided not to have a Division 5 anymore. Brilliant.

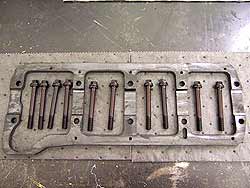

The Moroso main cap girdle in

all it’s glory. Simple and highly effective this

little gem will hopefully keep the Hemi-eater in one piece!

|

So, I went a different route. I had another 302 HO block

that already had the water jackets filled and only needed

bored out to .060” overbore to fill the role. Considering

I didn’t want to build another ticking time bomb, I

needed a way to add strength to the block.

That’s where my friends at Moroso come in. Man I swear,

if I need it Moroso more often than not has it. Moroso has

recently come out with a Main Cap Girdle for small block Fords

(part # 22928) made out of ½” chrome moly steel

that simply bolts to the main caps with the included fasteners,

and as usual for Moroso it actually fits! The included locating

washers actually tie the girdle into the main caps making

a cohesive unit with the new bolts and make for a much more

rigid bottom end. I think, and hope, this will end the bottom

end problem.

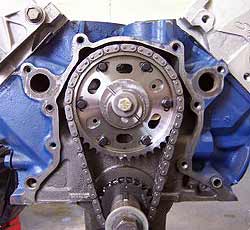

This is the Comp Cams Ultimate

Timing set. The six black bolts are the retention for

the two pieces of the sprocket. Simply loosen the bolts,

turn the outer gear to specs. and you have changed cam

timing! Nice! |

After fitting in new Durabond Teflon coated cam bearings

and file fitting new rings I installed the same Comp Cams

hydraulic roller stick I used last season and installed the

stock Ford crank, I-beam rods, and CP Pistons from before.

The only gear train change was a switch to Comp Cams new Ultimate

Adjustable timing chain set (part # 8138). This is a really

tricky piece of hardware that allows very easy and accurate

adjustability of cam timing. Basically, the cam gear is a

2-piece unit that rotates within itself using a provided adjustment

tool and all you do is line up the marks for whatever advance

or retard position you desire. One neat feature is you don’t

have to back of the rockers to allow movement because the

inner part is attached to the cam and the outer will rotate

with the crank when you loosen the holdown fasteners. Once

you're set, simply tighten the ARP bolts and away you go!

|