At the end of the 2011 race season the 632 Chevy we have been running for several years was clicking off 7.70 ETs at 170 and all seemed good. We took the engine out in November with the idea of having the crank, rods and pins magnafluxed and the aluminum block cleaned and thoroughly inspected.

WOW! Am I glad we had it checked. This is the engine we broke a rod bolt in during the 2010 season and had the block repaired, new rods, pins and pistons put in. We had about 180 runs on in 2010 and during 2011. Here is what we found:

1. The block repair was not all that great as can be seen by the "hole" left in the main webbing. The welding for the sleeve register was good but during the sleeve installation someone gouged the cylinder wall with a die grinder. The sleeves were in need of replacement as they had been honed as far as we could during the two rebuilds the engine has had.

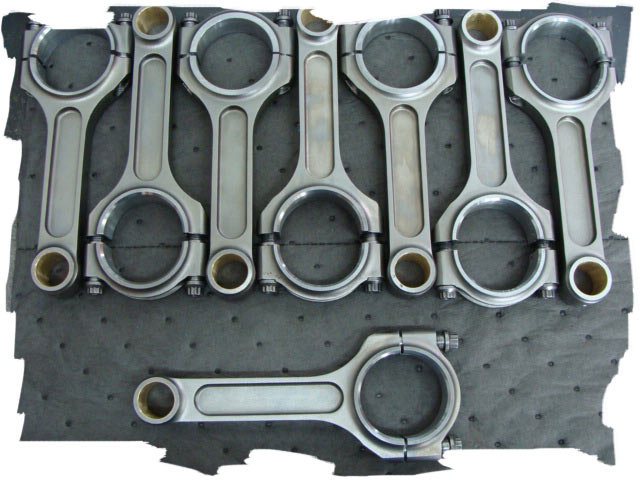

We had used the Ohio Crankshaft H-beam rods for three years and thought we would upgrade to their super-duty I-beam rods. Very nice pieces with ARP2000 fasteners, Jay checked them and all they needed was a little honing on the pin bushing to get the correct clearance.