|

|

|

||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

|

Drag Racing Online brings you a step-by-step series of tech articles

on purchasing, building and racing a rear engine dragster. Check back

to this site for frequent updates to watch our progress .

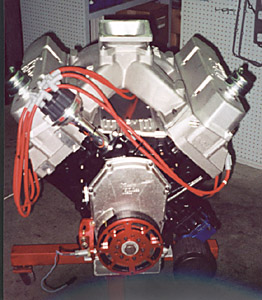

This article will deal with a couple of "major decisions" (as in expensive) that you will have to make if you are building a new dragster. The engine selection is a tough one. There are a lot of quality engine builders out there that offer super reliable big inch engines and also a wide selection of smaller engines at very affordable costs. Just do a lot of research and make sure you know EXACTLY what you are getting and what you have to provide BEFORE you make the commitment to order one. Can you still build your own engine or use your old "trusty" engine out of your soon to be retired bracket car? You sure can. What I found out while asking around is that dragster burnouts and the inherent "rattling" of the tires at the end of a burnout is hard on crankshafts and connecting rods. If you are using stock cranks and rods you will need to check them regularly. My opinion on this was to "start fresh." Of course, being the MOPAR freak I am I started looking at engine kits and building it at home or going with an assembled engine built by a professional. I called all the MOPAR engine builders and suppliers and had a bunch of information in front of me. After about two months of calling and faxing these guys with questions I was ready to decide. I chose Indy Cylinder Heads to build the engine and after talking to Indy's main man, Ken Lazzeri, we decided their 540 Bracket Master would be the best choice. I wanted enough power to get me into the local Quick 16 shows but not so much power that I couldn't get down our local tracks in the heat of July and August. I think Ken was totally honest with me. His "No B.S." straightforward attitude caught me a little by surprise, but he is a very busy man building some of the most powerful and reliable MOPAR engines in the country. If you want the facts, he is your man; if you want someone to "hold your hand" while you are deciding, look elsewhere. His expertise and experience will guide you in the right direction. He told me not to worry about anything in the engine. He builds all his engines with the same attention to detail. It would be tested on the Indy dyno and then tuned to provide the best torque and horsepower. All I needed to worry about was scheduling a time to pick the engine up. (Oh yeah, and paying for it too!) Usually a 25 to 50% deposit is required to place the order and then the balance is due when it is ready to pick up.

|

|||||||||||||||||||||||||

|

Copyright 1999-2001, Drag Racing Online and Racing Net Source |

|

||||||||||||||||||||||||

The Indy 540" Bracket Master is based on a much lightened (through a

lot of CNC machining) cast iron MOPAR Mega-Block (an aluminum Indy Maxx-Block

is available for about $2000 more for the weight conscience racers).

A 4.50" stroke Callies crank is held in place by the cross-bolted mains

of the Mega-Block. Eagle's latest steel rods hang from custom Wiseco

pistons. [crank.jpg] and {msd-ati.jpg] The real power for this combination

comes from the Indy 440-1 cylinder head package. Ken did a "max flow"

job on the heads and intake manifold. There are different ways to port

the heads for every combination and that is why you should choose an

engine builder that knows what you need.

The Indy 540" Bracket Master is based on a much lightened (through a

lot of CNC machining) cast iron MOPAR Mega-Block (an aluminum Indy Maxx-Block

is available for about $2000 more for the weight conscience racers).

A 4.50" stroke Callies crank is held in place by the cross-bolted mains

of the Mega-Block. Eagle's latest steel rods hang from custom Wiseco

pistons. [crank.jpg] and {msd-ati.jpg] The real power for this combination

comes from the Indy 440-1 cylinder head package. Ken did a "max flow"

job on the heads and intake manifold. There are different ways to port

the heads for every combination and that is why you should choose an

engine builder that knows what you need.