|

<<

PREVIOUS PAGE

Before I set them in for some trial fitting

I installed the half-inch thick AuVeCo foam

weather stripping. This will make sure the windows

are fitted at the correct height. When you are

deciding on what thickness of weather stripping,

you want to just measure from where you want

the outside of the window to the where the weather

strip will sit. I allowed for 1/8-inch compression

of the rubber for tightening and to make sure

it sealed.

When you are looking for a rubber seal, try

to find automotive weather stripping as it is

a closed cell foam and will not absorb water.

If you use regular household foam it may soak

up water and stay wet, which can rust the window

opening and discolor the foam seal. I found

what I needed at a local auto body supply store.

A fifty-foot roll cost me $28.00 and I used

about forty feet getting it finished. One side

had adhesive on it so it stayed in place and

worked out just great.

|

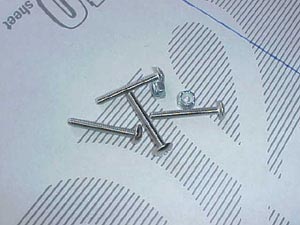

| I

recommend using stainless mounting

hardware so you won't have to deal

with rust problems. I chose 10-24

Phillips head stainless steel machine

screws with oversize head. Fifty of

them cost $4.25 and nyloc stainless

nuts cost $5.24. |

|

When you are trial fitting everything it is

a good idea to use a grease pencil and mark

where you want the mounting holes drilled. Look

for problem areas that will be hard to reach

or where there is already a hole that you do

not want to hit while drilling. When I found

where I DID NOT want to drill I measured the

opening and divided the distance into equal

parts. I ended up with approximately five inches

between my mounting screws. I am not sure if

they should be closer or if they could have

been spread apart more but it is a starting

point that looks pretty good. The key to this

whole deal is TAKE YOUR TIME and CHECK IT TWO

MORE TIMES BEFORE YOU DRILL THE MOUNTING HOLES.

I used a drill size that was 1/16-inch larger

than the 10-24 stainless machine screws I used

to retain the windows. This should prevent cracking

the Lexan when it expands and contracts in the

heat and cold. DO NOT OVERTIGHTEN the mounting

screws, I pulled them down until the foam sunk

about 1/8-inch. Use self-locking NyLoc nuts

so they will stay in the position you tighten

them to.

Here is a close up of the windshield after

installation. After I had everything fitted

and drilled I masked off about two inches

on the inside of the window and painted

it with semi-gloss spray paint. It gives

it a very nice finished look, can't peel

or chip because it is on the inside, and

covers up the windshield opening and

weather stripping. |

This is the Lexan side window. You can

see the mounting screws and the black

weather stripping. I tightened the screws

down about 1/8-inch after the Lexan hit

the weather strip. |

The next "little project" was finishing the

wiring. I have it about 95-percent done and

will complete it all when the engine is installed

and I know exactly where the water pump and

fan wires need to be as well as the wires to

the coil and distributor. I have the main battery

cables installed and the master shut-off switch

done as well as the wires from the switch panel

to the terminal strips I will use to hook up

items like the water pump, fuel pump, lights,

ignition, fans, etc.

As I have done with most of this car I did

a lot of "garage engineering" rather than just

ordering some of the stuff. The master disconnect

switch would have been easier to just mount

through a hole drilled in the back body panel

but I also wanted a way to turn off the power

(or turn it on) from the driver's seat. This

meant a small rod and a knob in back of the

car that is connected to the master switch.

NEXT

PAGE >>

|