|

<<

PREVIOUS PAGE

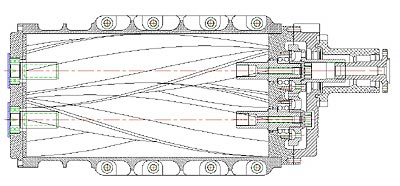

SCREW TYPE

Mechanical superchargers are either positive

displacement or not. A screw compressor is the

most efficient type of positive displacement

type supercharger available. The screw is just

as the name insinuates the rotors appear to

screw into each other. A screw compressor has

a male and female rotor where only one rotor

displaces air. Because of this, the rpm at which

these units run is greater than a roots design.

The internal tolerances of the screw compressor

are very tight, and the inter-twined rotors

act as a seal against any leakage up through

the rotors. The screw has an inlet cavity that

decreases in size as the rotors rotate. This

compresses the air charge internally, because

of this it can be called an air compressor.

The screw is known to be a very powerful supercharger

design, while the rotors are large and can be

heavy it is commonly over 200 horsepower over

a roots supercharger. The reason for this power

difference is the combination of lower discharge

temperatures and lower parasitic drag because

of no rubbing internal parts.

ROOTS SUPERCHARGER

The Roots supercharger is the old tried and

true positive displacement design used since

the GMC introduction on diesel trucks and even

earlier in coal mines to move valuable air to

the soon to be cancer victims at the bottom

of the mine.

The

Hi-Helix (left) and Standard Helix superchargers. The

Hi-Helix (left) and Standard Helix superchargers.

The Roots has two rotors with three lobes per

rotor. The Roots supercharger has two rotor

types, the Hi-Helix and the Standard Helix.

The high helix rotors are called 120-degree

rotors and the standard rotors are called 60

degree. This is the amount of rotor twist over

the length. Both rotors in the Roots design

displace air, giving the roots a large displacement

per rotation.

The size of the supercharger is based from

the rotor length. A 6-71 supercharger has a

15-inch long rotor, and an 8-71 has a 16-inch

one. This keeps going until the 16-71, which

has a 20-inch long rotor.

This

is Kobelco's 14-71 supercharger. This

is Kobelco's 14-71 supercharger.

Roots superchargers use Teflon sealing strips

to help seal small clearances between the rotors

and also to seal rotor to bore. These Teflon

strips need replacing from time to time to keep

the blower to its peak efficiency.

CENTRIFUGAL SUPERCHARGERS

Centrifugal superchargers are belt-driven turbine

wheels that compress air centrifugally (outward

from the center) with rpm. The impeller in the

supercharger causes air to move from the center

of the turbine and is accelerated outwards towards

the turbine housing and is then directed to

the outlet ducts. The rpm at which these superchargers

operate is very high, upwards to 30,000 plus

rpm. The centrifugal supercharger uses the same

compressor theory as a turbocharger except that

the means for driving the compressor is from

the crankshaft via belt. The supercharger has

a large gear ratio internally to bring the unit

to its needed rpm.

This type of supercharger notoriously makes

good boost pressures, but is much slower than

the positive displacement type superchargers

at building this valuable intake pressure.

NEXT

PAGE >>

|