|

RPS Performance Products has attacked these problems head

on and created a patented solution. By segmenting the flywheel

friction surface into four pucks, each puck can expand and

contract in its own CNC machined pocket without affecting

the other pucks. The steel pucks, unlike the one-piece hoop,

have some room to grow.

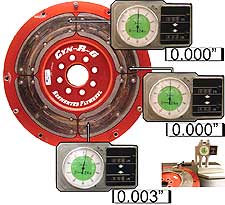

Even though this RPS Cyn-R-G flywheel

had obviously seen some heavy action, flatness measurements

were still within specification.

|

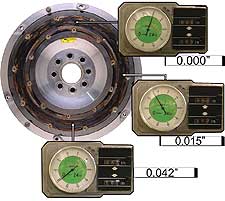

This aluminum flywheel with a

one-piece heat shield had seen some action, yet measurements

showed the surface beyond specified limits. Look closely.

The six-puck disc became so hot it fused to the heat shield

in six spots. Tip: keep the clutch pedal depressed after

a hot run. |

Because the flywheel surface stays flatter it stays cooler,

and this coolness helps the entire clutch last longer and

perform more consistently. The steel pucks can be replaced

for about the price of a flywheel resurfacing and RPS has

even carried though the segmented design to their Pro MAX

series pressure plates. Why replace the entire flywheel or

pressure plate when the friction surface is the only thing

that's worn?

HARD CORE

As it turns out being able to replace the flywheel and pressure

plate friction surface is a good idea, as the problem of flywheel

hot spots runs deep. RPS had one client with a mysterious

clutch problem. In replacing strip and street-strip stock

Mustang clutches with high performance setups, roughly half

of the customers noted that their clutches chattered on engagement,

despite the fact the flywheels were resurfaced according to

specification.

RPS president Rob Smith mulled over the problem and asked

the technician one question. Out of the customers that experience

chatter how many are running with new flywheels? The answer

was none. Rob managed to get one of the chattering flywheels

in question back to Los Angeles for testing on a Rockwell

hardness measuring device, and the results solved the mystery.

Even though the machining was spot on perfect, the flywheel

cast iron was harder in some spots than others. Excessive

heat had created a flywheel with material of different densities

despite being machined perfectly flat - the hot spots had

gone deeper than could be machined away.

The result was that the clutch disc matrix grabbed the flywheel

quicker in some spots than others and created chatter on engagement.

The only solution in these cases was to start over and use

a new flywheel – an expensive proposition at best. With

a replaceable friction surface new flywheel performance can

be attained for the cost of a stock flywheel resurfacing.

THE MATRIX

The matrix in this case has nothing to do with sci-fi, but

instead refers to the collection of materials, resins, modifiers,

fabric, and other top secret stuff that comprise the clutch

disc friction material as a whole. How these friction materials

grip to flywheel surfaces is part of the formula for clamping

force. The clutch disc matrix literally plows into the microscopic

texture of the flywheel and pressure plate surface and locks

up to create grip. Think about trying to walk with a set of

socks on a hard wood floor. Slip and slide guaranteed. Those

same socks on carpet? Grip city and you're the Mayor.

These same ideas apply to clutch discs and how well they

grip flywheel material. Chromoly, for instance, can be made

into a flywheel that's thinner and lighter, but has drawbacks,

as the material is also a lot harder. This hardness means

it's smooth on a microscopic level, and requires more friction

to create the same grip as cast iron or steel. The paradox

is that the flywheel friction surface has to stand up to serious

punishment, but also has to be made of the softest material

possible in order to grab the clutch disc matrix.

"Let's say you have a six puck with a chromoly flywheel,

vs. an organic with a cast iron flywheel, it's quite possible

the organic with the cast iron will hold more than the six

puck with the chromoly because the chromoly is particularly

hard. You can't just jump off and say the six puck hands down

holds more," said Rob.

Thus the flywheel material has a great influence on the overall

holding capacity of a given clutch setup.

|