Check out Part One of Oldmobile-ology here.)

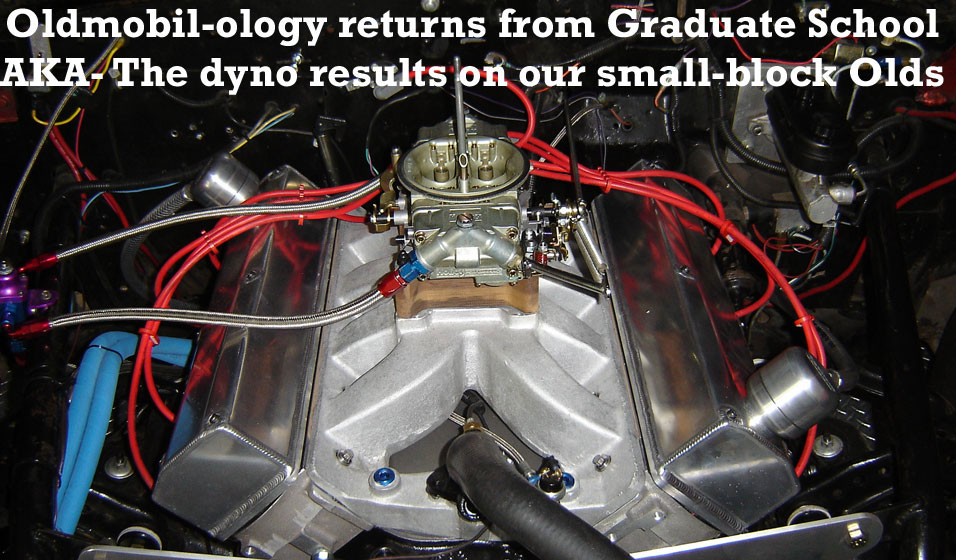

Last month we probably got our first look at the innards of a short block that wasn’t a Chevy, Mopar or Ford drag race engine. The small-block Olds that my friend Nick is having built at R&S Racing in Albert Lea, MN, has been assembled, sent to the dyno and is now between the fenders of Nick’s Cutlass. The results were fantastic and I think the entire engine combination more than delivered the power that everyone involved with the project expected.

This is the epoxy mold R&S made of the combustion chamber so Diamond Pistons could set up their CNC equipment to make the correct profile on the dome of the piston. This type of custom work is not very expensive but it is time consuming getting it ready. |

How do these numbers grab you for power from a small-block Olds?

730 HP, 579 lb-ft Torque with 425” small-block Oldsmobile!

When Nick called me with those numbers all I could think of was I better get some wheelie bars on the Olds! I won’t get into minute detail (you have to call R&S Racing for that) but I will provide you with basic information of what had to be done to the engine combo to get it to deliver the amount of torque and horsepower it does.

You know, I just realized that I had a 540” Mopar that made 780 HP and I thought that was awesome. Now it seems sort of weak when compared to this Olds engine that has 115 fewer cubic inches.

Tom and Lynn Hestness own R&S Racing in Albert Lea, MN. He won the Mopar Engine Shoot-out a few years ago with a very trick 410” small-block Mopar. His reputation for minutia is well known and it showed when he put Nick’s small-block Olds on the dyno.

Last month I briefed you on the block prep, and the crankshaft and now I will go a little deeper into how they got 730 HP out of this combination.