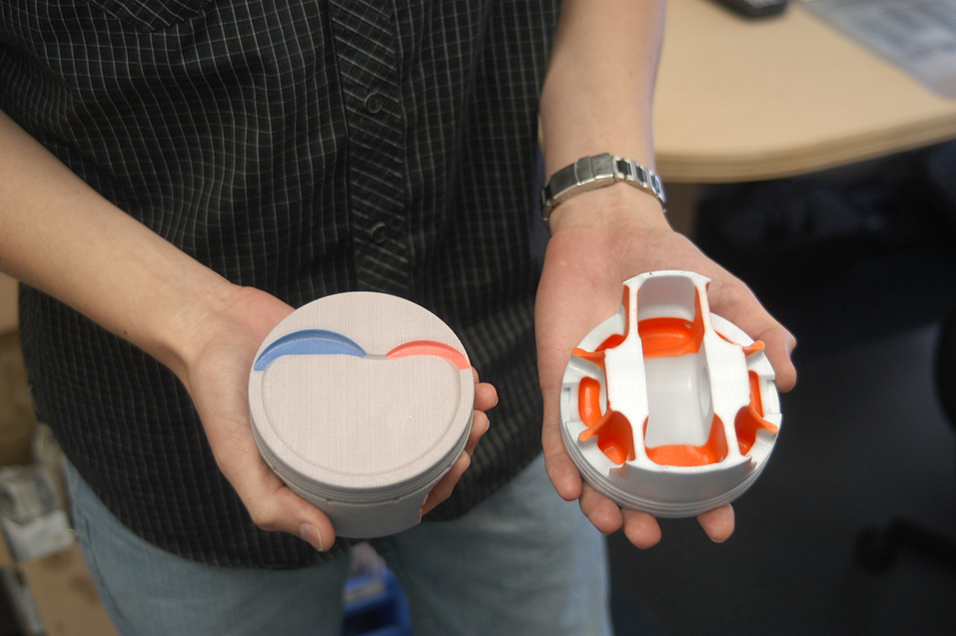

Rapid prototype pistons are made of plastic in a 3-D printer. They are valuable for verification prior to preparing forge tooling. Beyond this they are used to assess a series of requirements, including oil squirter clearance.

|

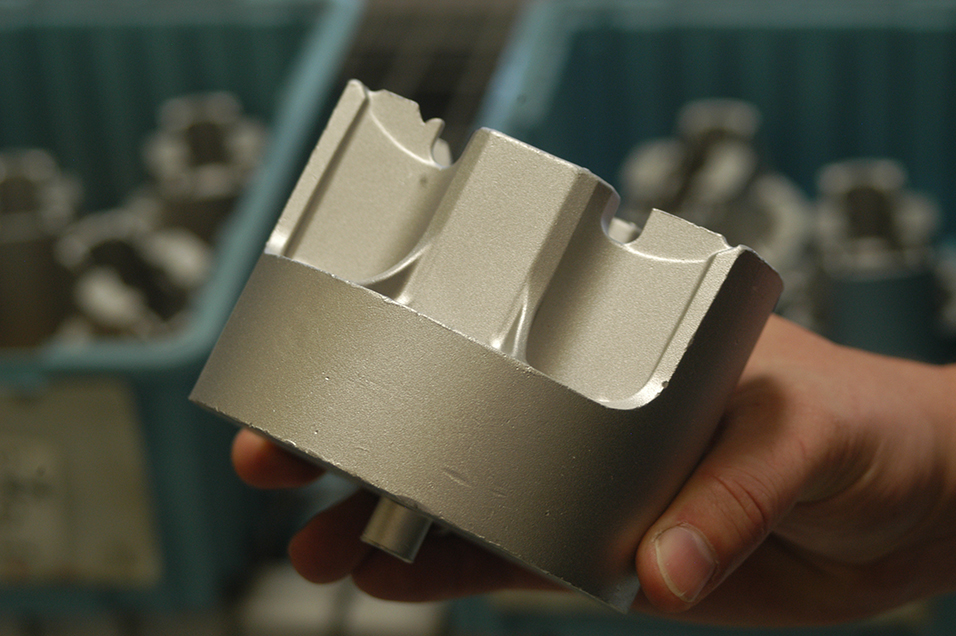

| Before shipping, pistons are measured with Coordinate Measuring Machines to ensure accuracy. |

How are the asymmetrical pistons made

JE Pistons actually manufactures their own forgings and has access to over 300 variations. To advance their levels of accuracy Coordinate Measuring Machines are used for final inspection. Three-dimensional apparatus, CMMs are employed for measuring the geometrical proportions of each piston. Acquiring this degree of accuracy earned JE an ISO 9001:2008 quality certification.

Snatching asymmetrical dominance in the LS piston market; JE manufactures their own forgings and claims access to 300 variations

For professional racers or performance enthusiasts seeking greater versatility than afforded by forgings, JE offers billet-style pistons. Billets accommodate infinite design objectives; they also permit last-minute changes in specifications for those tuners, engine builder and professional teams that altering their piston designs from race-to-race ie different compression ratios for racing at costal tracks versus tracks in Colorado or Texas that are 5000+ feet above sea-level.

Interestingly, drag racing applications represent nearly half of JE’s business, but they also produce race pistons for various other applications including those competing in NASCAR, Indy Car, Tudor United Sportscar, and all categories of motorcycle racing.

Source

JE Pistons

714-898-9763

www.JEPistons.com ![]()